We started the building process as we often do, by scarfing and coating the plywood to be used for hull planking. The bottom in this boat will be cold-molded with three layers of 6mm ply laid double diagonal. The topsides will also be cold-molded, with 2 layers of 4mm ply laid double diagonal and a top layer of 1/8" Khaya veneer laid fore-and-aft to hide the double-diagonal seams. Even though all these pieces to be used in the cold-molding will be relatively short, we scarf the plywood into long sheets to minimize waste and to make it more convenient to coat.

Here we see some 32' lengths of Okoume ply being scarfed, while some already scarfed and coated Sapele ply leans against the wall. The Sapele will be used for the inner and outer layers of the bottom to increase strength and durability.

That done, we turn our attention to the longitudinal members of the vessel. Here we see topside stringers, inner chines, and the laminated keel being prepared for epoxy coating.

Laminating the stem from 3/8" Khaya.

The stem looked like this after we cleaned it up and before beveling to take the planking.

Meanwhile, we proceed to laminate and cut out the Khaya frames, working from Mylar templates. These are good-sized frames, and they need to be since this will be quite a fast boat, designed to take a lot of punishment in the open ocean.

Having made the frame parts, we assemble and coat them with epoxy. These frames will go under the cockpit sole.

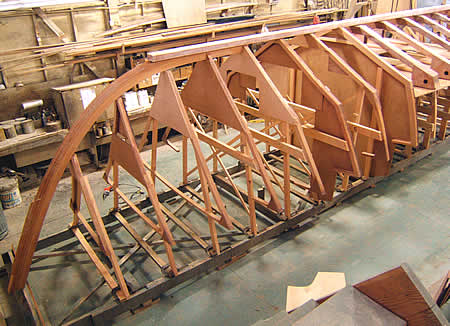

The forward frames, jigging legs on and ready to set up.

And the aft frames are also ready. The fir molds will shape the topsides in the cockpit area. The frames in the engine compartment are behind them, followed by the transom frame.

After all the parts are made we stack them up for a preliminary check.

Then we notch the bulkheads

for the stringers and start installing longitudinals. Here the keel and inner chines go in.

This shows structures below the cockpit sole. Some of these structures drain the water from around the hatch covers and lead it all the way aft and out through the transom. The cockpit sole is supported by a system of frames and stringers, just like the hull, only smaller in size. We can also see the engine beds in the engine compartment.

Then it's time to install stringers in those notches. The bottom stringers are Khaya, while the topside stringers are VG Douglas fir. The upper topside stringer still needs to be installed. The keel and chine will be faired into the structure in the next step.

But before we do that, we'll have the tanks made and fit them into the bilge. This boat will carry 200 gallons of Diesel in 4 tanks, all of which can be removed for inspection if necessary.

The keel, chine, and stringers are now faired down and we are planking the hull. The bottom will be cold-molded of three layers of 6mm plywood, laid triple diagonal. This is not a developable shape, so it must be cold-molded. Because the shape is so easy in the stern, we can use 2'-wide plywood pieces as you see we are doing here. The pieces will get narrower as we move forward. We will dry-fit the whole first layer before gluing it down to the framework.

From the stern. We installed the transom after all the stringers, etc. were installed and faired, then we started planking. You can see that actually the first piece we put on the bottom was 4' wide, then we started with the 2' wide pieces.

Now we have the entire first layer of the bottom dry fitted. Note the deep forefoot that is characteristic of this hull form.

Another view of that deep forefoot. With a little effort, you can imagine the lovely bow wave this bottom will make.

And another, highlighting the sweeping chine line and high bow deadrise.

More photos to follow soon.

|